New publication from WEST researchers describes the barrier effect of membrane distillation against microbes

Environ. Sci. Technol. Lett. 2021

Reclaimed water can contain viruses that need to be removed prior to potable reuse or other applications. Fortunately, membrane processes such as ultrafiltration and reverse osmosis (RO) have been shown to be effective at removing viruses and other contaminants from this type of a water. However, RO produces a concentrate (waste) stream which contains high concentrations of pathogens and contaminants that often requires treatment and volume reduction before disposal.

To determine if an alternate process, high temperature membrane distillation (MD), might be an effective alternative, WEST Center researchers from the Chemical and Environmental Engineering Department (CHEE) and the Environmental Science Department (ENVS) engaged in a collaborative project. Together, these researchers investigated the effects of high temperature MD on viable virus concentration and membrane rejection of viruses. As stated in the newly published article:

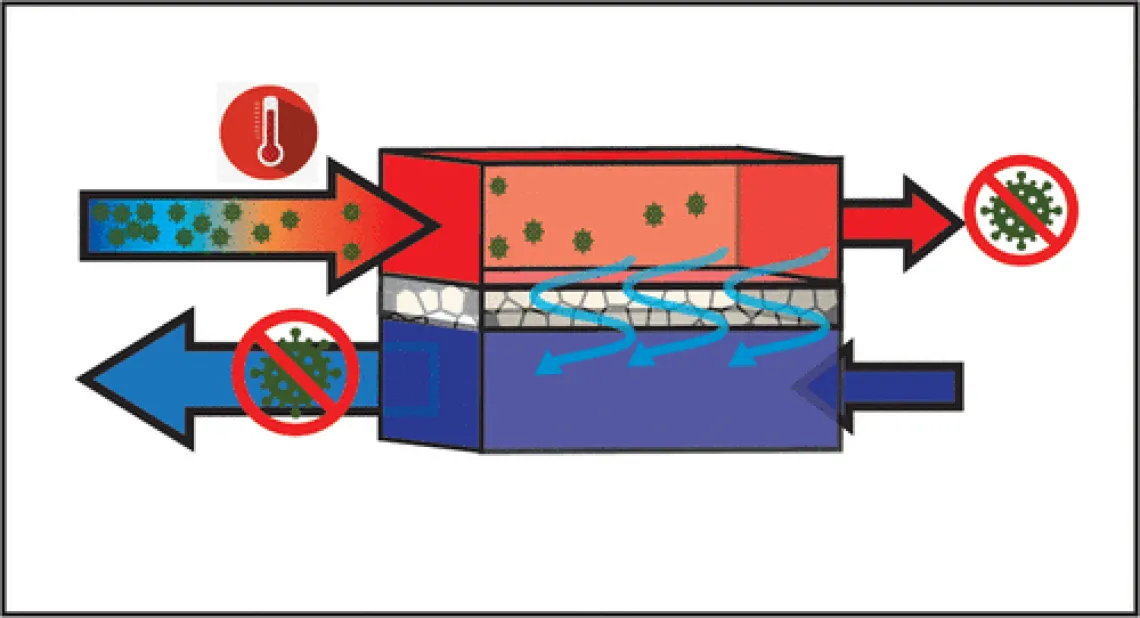

“Membrane distillation (MD) is a treatment process that can reduce reverse osmosis (RO) concentrate volume [by boosting water recovery] while augmenting the potable water supply. MD is also a dual barrier approach for virus removal as it operates at a high temperature and permeates only the vapor phase through the membrane interface.”

Performing experiments using two nonenveloped phages frequently used as enteric virus surrogates (MS2 and PhiX174) and an enveloped pathogenic virus (HCoV-229E), researchers discovered that at typical MD operating temperatures (greater than 65 °C), viable concentrations of all three viruses were reduced by thermal (heat) inactivation, and membrane rejection increased.

In the article, Membrane Distillation Provides a Dual Barrier for Coronavirus and Bacteriophage Removal, authors Hardikar, Ikner, Felix, Presson, Rabe, Hickenbottom, and Achilli explain:

“In conventional membrane processes such as RO or nanofiltration (NF), virus rejection is achieved by size exclusion and is thus dependent on membrane integrity for complete rejection.(20) In MD, the high operating temperature can reduce virus concentration in the feed and provide an additional barrier in the event of membrane damage. Additionally, as only the vapor phase permeates through the hydrophobic membrane, MD can theoretically reject 100% of nonvolatile solutes in the absence of pore wetting. However, recent studies have observed the transport of nonvolatile hydrophobic compounds even through nonwetted pores via hydrophobic interactions with the membrane.(21,22) Therefore, it is important to investigate the rejection of viruses that are characterized by varying degrees of hydrophobicity. The objective of this study is to evaluate MD as a dual barrier process for virus reduction in the feed and removal from the distillate” (emphasis added).

Study results showed a high rejection of viruses and viral inactivation at elevated temperatures, demonstrating that “MD is well suited for the treatment of enveloped viruses. More importantly, in the case of membrane failure, MD provides a safeguard via thermal inactivation for operating temperatures over 50 °C, thus ensuring high virus removal.”

The article was published in Environmental Science and Technology Letters (Environ. Sci. Technol. Lett.) in July 2021. To read the full paper, follow the link here.

Information about WEST researchers can be found in the WEST Directory and Student Directory. Additional information about first author, Mukta Hardikar, and other engineering faculty and students involved in the study can be found on the Achilli Research & Teaching Lab website.

* * * * * * * * * * * * * * *

Antony, A.; Blackbeard, J.; Leslie, G. Removal Efficiency and Integrity Monitoring Techniques for Virus Removal by Membrane Processes. Crit. Rev. Environ. Sci. Technol. 2012, 42 (9), 891– 933, DOI: 10.1080/10643389.2011.556539

Meng, S.; Ye, Y.; Mansouri, J.; Chen, V. Fouling and Crystallisation Behaviour of Superhydrophobic Nano-Composite PVDF Membranes in Direct Contact Membrane Distillation. J. Membr. Sci. 2014, 463, 102– 112, DOI: 10.1016/j.memsci.2014.03.027

Han, L.; Xiao, T.; Tan, Y. Z.; Fane, A. G.; Chew, J. W. Contaminant Rejection in the Presence of Humic Acid by Membrane Distillation for Surface Water Treatment. J. Membr. Sci. 2017, 541 (May), 291– 299, DOI: 10.1016/j.memsci.2017.07.013